When you design something new, chances are it starts as a CAD file. That’s the language engineers and product builders know best. But when it comes to filing a patent, the rules are very different. Patent drawings are not about beauty or branding. They follow strict legal standards so that anyone—an examiner, a judge, or even a competitor—can clearly understand your invention.

Why CAD Files Don’t Work as Patent Figures

At first glance, CAD models seem perfect for patents. They’re precise, detailed, and show exactly how your invention works. But patent offices don’t see them the same way.

The standards for patent drawings are not about technical depth but about clarity and legal precision. If you send in CAD exports as they are, you’ll almost always run into problems.

The reason is simple. CAD was built for engineers. It’s designed to show every feature in exact proportion, often with layers of details that only make sense in a design or manufacturing context.

Patent drawings, by contrast, are built for examiners and judges who need to understand your invention quickly, without being distracted by unnecessary complexity.

The mismatch between these two worlds is where most inventors get stuck.

Too Much Detail Hurts Your Case

CAD files are often overloaded with information. Every curve, bolt, and measurement is captured. But in a patent application, showing too much can be risky.

If your drawings highlight features that are not central to your claim, it could lock you into a narrower patent. Competitors may later use that against you, pointing out what you excluded or overemphasized.

The better approach is to simplify. Focus your figures only on the elements that matter for the invention’s function and novelty. This doesn’t mean you hide information.

It means you decide what’s essential for protection and strip away everything else. That strategy makes your patent stronger and harder to work around.

Shading and Perspective Don’t Translate

CAD models often rely on shading, gradients, and realistic rendering to make sense visually.

Patent drawings, however, must stick to clean black-and-white line work, often with uniform stroke weights. Shading is rarely allowed, and when it is, it must follow very specific conventions.

This is why simply exporting an image from CAD won’t work. You’ll need to re-render your model into line drawings, choosing the views that communicate structure without relying on shadows or textures.

It may feel like a step backwards, but this stripped-down style ensures your drawings will meet the examiner’s requirements.

Multiple Views Are Mandatory

A CAD file is a 3D object you can rotate freely. But patent drawings require fixed, standardized views: front, top, side, perspective, sometimes sectional. Without these, your application will be considered incomplete.

CAD files don’t automatically generate legally compliant views. You have to intentionally set them up, decide which angles reveal the key features, and make sure they are consistent across the entire drawing set.

The Legal Standard Is Different

Perhaps the most important difference is this: patent drawings are legal evidence. They are not marketing images, engineering diagrams, or internal design files.

They must meet rules that are surprisingly rigid. For example, the US Patent and Trademark Office rejects drawings if margins are too tight, lines are inconsistent, or reference numbers are misplaced.

What seems like a small formatting detail can trigger a rejection and delay your filing.

Businesses often underestimate how costly those delays can be. A rejected filing doesn’t just slow things down; it can create openings for competitors, or even risk losing patent rights if deadlines are missed.

Actionable Advice for Businesses

If your team relies heavily on CAD, the smartest move is to build a clean handoff process.

Engineers should provide CAD models, but a designated person—whether in-house or through a platform like PowerPatent—should be responsible for converting those models into compliant figures.

This avoids the trap of sending raw exports to your attorney and expecting them to work.

Another strong move is to create a CAD-to-patent checklist tailored to your product line.

For instance, if you’re in hardware, decide in advance which standard views you’ll always include, how you’ll handle exploded diagrams, and what elements should be simplified.

Having this playbook saves weeks of back-and-forth when you’re filing under tight deadlines.

Finally, treat your patent drawings as strategic tools, not as an afterthought. Just as you invest in making your CAD files perfect for manufacturing, invest the same energy into making your figures perfect for protection.

The extra care upfront pays off when your patent sails through the examination process without hiccups.

And if you’d rather not reinvent the wheel, PowerPatent is built to make this transition smooth.

Our platform helps you go from CAD to compliant patent figures with expert oversight, cutting out the guesswork. You can see how it works here: https://powerpatent.com/how-it-works.

Breaking Down What Patent Drawings Really Need

Once you understand why raw CAD exports won’t work, the next step is knowing exactly what patent drawings must include. These requirements are not arbitrary.

They exist to make sure anyone reviewing your application—whether an examiner, a competitor, or a court—can clearly grasp what your invention is and how it works.

For businesses, this is where strategy kicks in. The right figures don’t just meet the rules; they help secure stronger, more defensible protection.

Clarity Over Complexity

The golden rule of patent drawings is clarity. Patent offices don’t want beautiful renderings; they want simple, easy-to-read visuals. Every line, every angle, and every reference number should serve a purpose.

If an examiner can understand your invention without guessing, you’ve done it right.

For companies filing multiple patents across a product line, this means adopting a consistent drawing style. When your figures look professional and uniform across filings, you send a message of credibility.

Examiners notice this. So do investors and potential partners who may later review your patent portfolio.

Showing Enough, but Not Too Much

A common mistake businesses make is either showing too little or too much. If you show too little, your patent may be rejected for being unclear.

If you show too much, you may accidentally lock yourself into details that competitors can avoid while still copying your idea.

The right approach is balance. Highlight the core features that make your invention novel, while leaving out unnecessary design details that don’t affect protection.

For example, if you’ve developed a new hinge mechanism, focus the figures on how the hinge operates, not on the decorative casing around it.

This balance is not just a drawing decision; it’s a business decision. You’re shaping how broad or narrow your protection will be. Getting this right early prevents costly disputes later.

Standardized Views Matter

Patent offices expect specific views: front, rear, side, top, bottom, and perspective. Sometimes, additional views such as sectional or exploded diagrams are needed.

Each one has a purpose, and missing even one required angle can lead to rejection.

Businesses that file regularly should standardize which views they always include. This creates efficiency and avoids last-minute scrambles.

For example, if your team always prepares six standard views plus one perspective, you reduce the chance of an examiner requesting revisions.

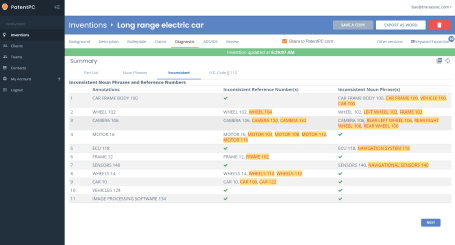

Reference Numbers Are Not Optional

Every key part of your invention shown in a figure must be labeled with reference numbers, which are then explained in the written description. This is how the figures and the text work together.

Without proper numbering, your application will almost certainly face objections.

The smart move here is to create a reference system that scales. If your company files patents for multiple related products, using consistent numbering conventions across applications will make drafting and reviewing much easier.

It also helps investors and partners see how your innovations connect as part of a larger portfolio.

Black and White Is Still the Standard

Even though CAD can render full-color 3D images, patent offices around the world still require black-and-white line drawings in most cases. Color is allowed only under very limited conditions.

This means your conversion process should strip away gradients, textures, and colors, focusing instead on clear outlines and uniform line weights.

This standard may feel outdated, but it exists for a reason: black-and-white images reproduce clearly across paper and digital systems, ensuring your patent remains legible decades into the future.

Actionable Advice for Businesses

To streamline this step, treat your patent drawings as part of your product development workflow, not as an afterthought.

When your engineering team finalizes a CAD model, immediately decide which elements should be highlighted in patent figures. This reduces the risk of later confusion about what’s essential.

Another smart tactic is to run a mock review. Before filing, share your draft drawings with someone outside your engineering team.

If they can understand the invention from the figures alone, you’re on the right track. If they can’t, you need to simplify further.

For businesses scaling fast, consider building an internal template for patent drawings that includes pre-set margins, line styles, and labeling conventions.

This not only speeds up each new filing but also builds a professional, consistent look across your patent portfolio.

And of course, if you want to eliminate the back-and-forth and make sure your drawings are right the first time, PowerPatent makes it seamless.

Our platform ensures your figures meet global standards while keeping your team focused on building, not formatting. You can explore how it works here: https://powerpatent.com/how-it-works.

Preparing Your CAD Model for Conversion

Before you can create patent-ready figures, you need to prepare your CAD model. This is where most businesses either save time or lose it.

If your CAD file is set up with clarity in mind, conversion to compliant figures becomes smooth. If it’s cluttered, inconsistent, or over-detailed, you’ll face delays, rejections, and costly edits.

Stripping Away What Doesn’t Matter

CAD models are full of features designed for manufacturing, like fasteners, threads, textures, and assembly tolerances. While these are important for building the product, they rarely belong in a patent drawing.

Showing them can either confuse the examiner or narrow your patent unintentionally.

The first step is to strip down the model to its essentials. Focus on what defines your invention’s novelty.

If your idea is about a unique locking system, highlight that mechanism and remove cosmetic or repetitive details that don’t add legal value.

This exercise not only cleans up your figures but also forces your team to think strategically about what aspects of the invention truly deserve protection.

Deciding on the Right Level of Detail

Patent drawings are not engineering specs. They don’t need to show micrometer precision or every internal component. Instead, they need to present the invention in a way that is clear and unambiguous.

The trick is to adjust the level of detail. Too much detail and you risk cluttering the figure. Too little detail and the examiner may not fully understand your innovation.

The goal is to strike the middle ground where the drawing is simple yet complete.

A good way to test this is to ask: could someone skilled in the field understand the invention by looking at the figures alone? If the answer is yes, you’re at the right level.

Setting Consistent Views in CAD

Patent offices expect specific angles. That means you should configure your CAD model in advance so that each standard view—front, rear, side, top, bottom, and perspective—shows cleanly and consistently.

If your team uses CAD daily, you probably already save default views. The difference here is that you need to refine them for patent clarity. Make sure no hidden parts obscure the key features.

Ensure the scale is consistent across views. Keep the angles simple rather than dramatic.

Doing this early prevents the need to redo views later, which can waste time and create inconsistencies across drawings.

Handling Complex Assemblies

For products with multiple components, CAD models often include full assemblies. While this is useful for design, it can be overwhelming for patent figures.

In these cases, it’s smart to prepare both simplified assembly views and exploded views that show how parts connect.

Exploded views, when used strategically, can strengthen a patent by making the relationship between parts unmistakable.

But the key is to keep them tidy. Remove background clutter, align components carefully, and use consistent spacing so the examiner sees function, not noise.

Checking for Compliance Early

A critical but often overlooked step is checking compliance before you export. Margins, line weights, and reference number placement all matter.

The earlier you spot issues, the less time you’ll waste cleaning up figures after conversion.

One way businesses can stay ahead is to adopt internal drawing standards that mirror patent office requirements.

That means setting up your CAD output so that margins, line thickness, and spacing are always correct from the start.

Actionable Advice for Businesses

If your company files patents frequently, make CAD preparation a formal stage in your patent workflow.

Don’t treat it as a quick export at the end. Instead, assign responsibility to someone who understands both the engineering and the legal standards. This bridge role saves enormous time when deadlines are tight.

Another tactical move is to create a reusable CAD layer system. Keep one version of the model for engineering and another stripped version for patents.

This way, you avoid confusion between what’s needed for production and what’s needed for protection.

Finally, think of CAD preparation as risk management. By cleaning your files and setting up views properly, you’re reducing the chance of costly office actions or delays.

The upfront work pays off by getting your application accepted faster, with fewer revisions.

If this feels like a lot to juggle, you’re not alone. Many teams hit bottlenecks at this stage. That’s why PowerPatent streamlines the process, turning CAD files into compliant figures with expert oversight. You can see how it fits into your workflow here: https://powerpatent.com/how-it-works.

Turning 3D Models into Clear 2D Patent Views

Once your CAD model is stripped down and prepared, the real challenge begins: turning a three-dimensional design into a set of two-dimensional patent figures. This step is where engineering habits often clash with patent standards.

Engineers are trained to communicate through complex 3D visualizations, but patent examiners need flat, clean drawings that are consistent and standardized.

Why 2D Matters in a 3D World

Even though your invention lives in 3D, patent drawings must be 2D line illustrations. This is because patents need to be reproducible, easy to archive, and legally precise.

A flat figure removes ambiguity, ensuring that someone decades from now can still understand your invention without specialized software or rendering tools.

For businesses, this requirement forces a shift in mindset. The goal isn’t to wow the viewer with depth or realism—it’s to make the invention impossible to misinterpret.

Choosing the Right Views

When translating a 3D model into 2D drawings, the key is to pick views that tell the story of your invention.

At a minimum, this usually means front, rear, left, right, top, bottom, and a perspective view. But not every view adds value in every case.

For example, if your invention is symmetrical, you may not need to show every side in detail. If your innovation lies in the internal mechanism, you might need a cross-sectional view.

The decision should always tie back to what needs protection.

This is where strategy meets design. Don’t just export every possible angle. Choose the ones that highlight the novel features clearly, without overloading the examiner.

Flattening Without Losing Meaning

The hardest part of converting CAD to patent views is flattening the model while keeping the important details visible. A line drawing doesn’t have the luxury of shading or depth cues.

If you’re not careful, flattening can make features overlap or disappear.

The solution is careful use of broken lines, cutaway views, or exploded views. Broken lines can show hidden features without crowding the figure. Cutaway views can reveal internal components in a clean way.

Exploded views can illustrate how parts fit together without overwhelming the page. Each of these tools should be used intentionally, not automatically.

Maintaining Consistency Across Views

Another challenge is consistency. Every view of your invention should align with the others. If the front view shows a feature, the side and top views must show it in proportion.

If reference numbers are used, they must be identical across all drawings.

Inconsistent drawings create confusion for examiners, which can lead to objections. Worse, inconsistency can be exploited later by competitors in court, arguing that your patent is unclear.

For businesses filing multiple patents, adopting a disciplined system for numbering, scaling, and positioning views is essential.

It’s not just about getting one patent right—it’s about creating a portfolio that holds up under scrutiny.

Avoiding CAD Export Traps

Most CAD software offers an option to export 2D views. While tempting, these exports often fall short of patent standards. The lines may be too thin or inconsistent.

The margins may be off. Hidden edges may show up unintentionally. Using these exports without adjustments is one of the biggest traps businesses fall into.

Instead, treat the CAD export as a starting point. Refine it manually or through a specialized tool to ensure compliance. This may mean redrawing certain views or cleaning them up in a vector-editing program.

It takes more time upfront, but it saves weeks of rejections and revisions later.

Actionable Advice for Businesses

Think of your 2D patent views as a communication tool, not a technical output. The examiner is your audience. If they can’t quickly understand your invention from the drawings alone, you haven’t done enough simplification.

One strong tactic is to stage a quick internal review. Share the draft figures with someone outside your engineering team—maybe a sales or operations colleague.

If they can point out the unique feature without needing an explanation, your figures are clear. If they can’t, refine further before filing.

Another practical move is to create a master template for 2D views. This ensures every patent filing your company submits looks consistent, with standard margins, line weights, and numbering conventions.

Over time, this consistency builds trust with examiners and strengthens your company’s patent brand.

And if your team doesn’t want to spend valuable engineering hours cleaning up drawings, this is exactly where PowerPatent can help.

Our platform takes your CAD models and produces patent-ready 2D figures, overseen by real patent attorneys who know the compliance rules inside out. You can explore how it works here: https://powerpatent.com/how-it-works.

Polishing and Checking for Compliance Before Filing

By the time you’ve converted your CAD into 2D patent views, you’ve done the heavy lifting.

But here’s where many businesses stumble: they stop too soon. Even a clean set of drawings can fail if they don’t meet the strict formatting and compliance rules set by patent offices.

Polishing your figures before submission is the last safeguard between you and costly delays.

Why the Final Review Matters

Patent drawings are not judged on effort—they are judged on compliance. That means if margins are off by a millimeter, or if reference numbers aren’t placed correctly, the examiner won’t hesitate to reject them.

This doesn’t just add frustration; it can push your filing back by weeks or months. For startups racing against competitors, that lost time can be the difference between owning a market and playing catch-up.

A polished review ensures your drawings are not just clear but also bulletproof.

Think of it as proofreading before publishing an important press release. You wouldn’t send out something riddled with errors, and the same applies here.

Common Pitfalls to Avoid

Some errors show up again and again when businesses rush drawings. Line thickness is one. Patent offices want uniform lines, typically neither too light nor too heavy, so the figures reproduce cleanly.

Another common issue is overuse of shading, which is only allowed in rare cases. Shading that looks natural in a CAD rendering can cause instant rejection in a patent filing.

Margins are another detail that trips people up. Each office has exact requirements for page size and border spacing. A drawing that looks fine on your screen may not print correctly when submitted.

Even reference numbers—something as small as their placement—can sink an application if they are inconsistent, unclear, or overlapping with the figure.

Testing for Legibility

One of the best ways to check compliance is to print your figures in black and white, at the smallest size likely to be used in review.

If the drawings are still clear, with no blurred lines or crowded details, you’re in good shape. If they’re hard to read, you need to simplify further.

This test is simple, but powerful. Patent examiners review hundreds of applications, and anything that slows them down becomes a liability for your filing. Clear drawings move your application forward smoothly.

Creating a Compliance Checklist

For companies filing regularly, it pays to build a compliance checklist. This ensures every figure you submit is reviewed against the same standards.

A typical checklist might cover margins, line weights, reference numbering, view consistency, and page formatting. Running every set of figures through this process creates reliability and reduces risk of rejections.

If you’re growing a patent portfolio, a checklist also ensures consistency across applications.

That consistency sends a signal of professionalism not just to patent offices but also to investors, partners, and potential acquirers reviewing your IP.

Building Internal or External Expertise

At some point, businesses face a choice: build in-house capability for patent drawings or outsource them to experts. Both approaches can work, but the right choice depends on your growth stage.

Startups with limited resources may benefit from outsourcing, as it saves valuable engineering time and ensures compliance without a steep learning curve.

More established companies may choose to train a dedicated team to handle figures in-house, especially if they file frequently.

Either way, the key is recognizing that patent drawings are not a side task. They are a critical part of your IP strategy. Treat them with the same seriousness as financials or product specs, and you’ll avoid costly missteps.

Actionable Advice for Businesses

A smart practice is to schedule a final drawing review before every filing deadline. Make it part of your workflow, just like legal review or signature collection.

Assign clear responsibility for this step so it doesn’t get lost in the shuffle.

If you’re managing a portfolio, maintain a digital archive of all approved drawings. This not only helps with future filings but also ensures you can easily reference older patents during fundraising, licensing, or litigation.

Most importantly, remember that compliance is not about artistic quality—it’s about legal strength. A figure that meets every rule is far more valuable than one that looks beautiful but gets rejected.

For many businesses, the fastest way to ensure polished, compliant figures is to use a platform built for this exact step.

PowerPatent combines automation with attorney oversight, so you can be confident your figures won’t just look right, but pass examiner review without delay. If you’d like to see how it works, you can check it out here: https://powerpatent.com/how-it-works.

Wrapping It Up

Converting CAD files into patent-ready figures may sound like a small step, but it’s one of the most critical moves you can make when protecting your invention. Raw CAD exports won’t cut it. Patent offices demand clarity, precision, and strict compliance, and the way you present your figures can make or break your application.